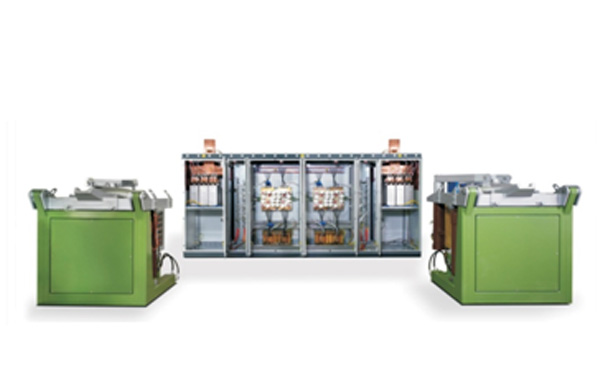

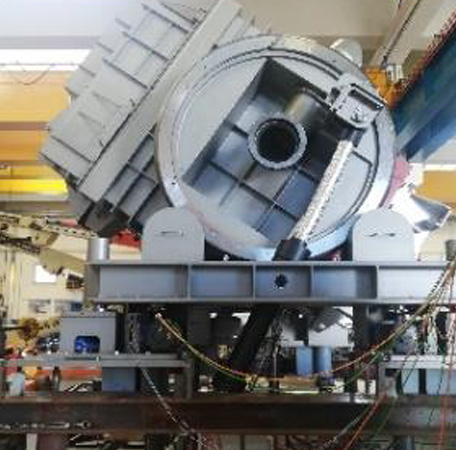

GMS produces a wide range of Low (Mains) and Medium Frequency Melting and Holding Coreless Furnaces for ferrous, non-ferrous and precious metals. GMS Furnaces are designed to ensure the maximum efficiency and the best performance.

The GMS Low (Mains) Frequency Coreless-type Furnaces are used when the maximum mixing of the liquid bath is required for melting of both ferrous and non-ferrous metals.

Italiano

Italiano

Latest News