WET & DRY

GMS

Global Metallurgical Solutions

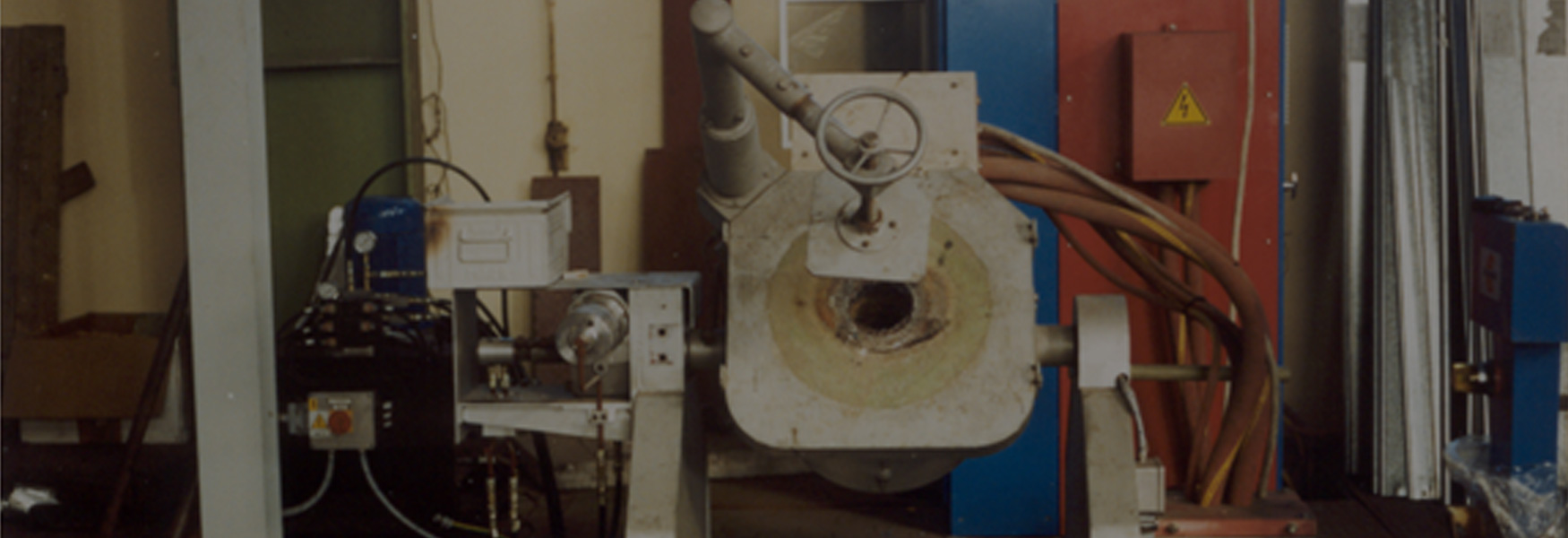

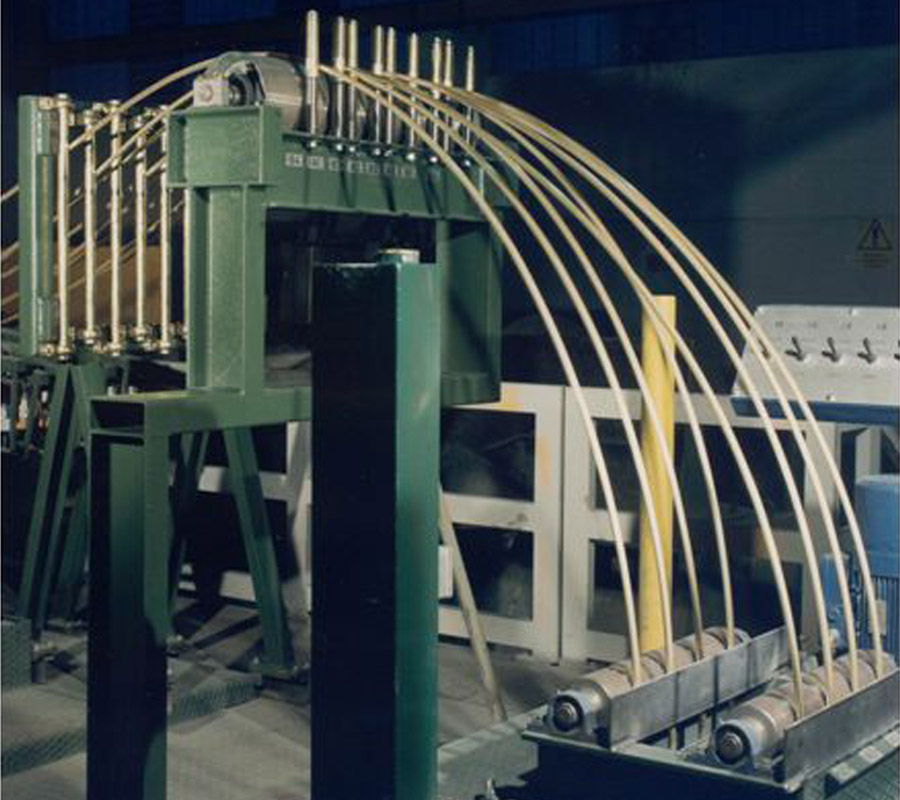

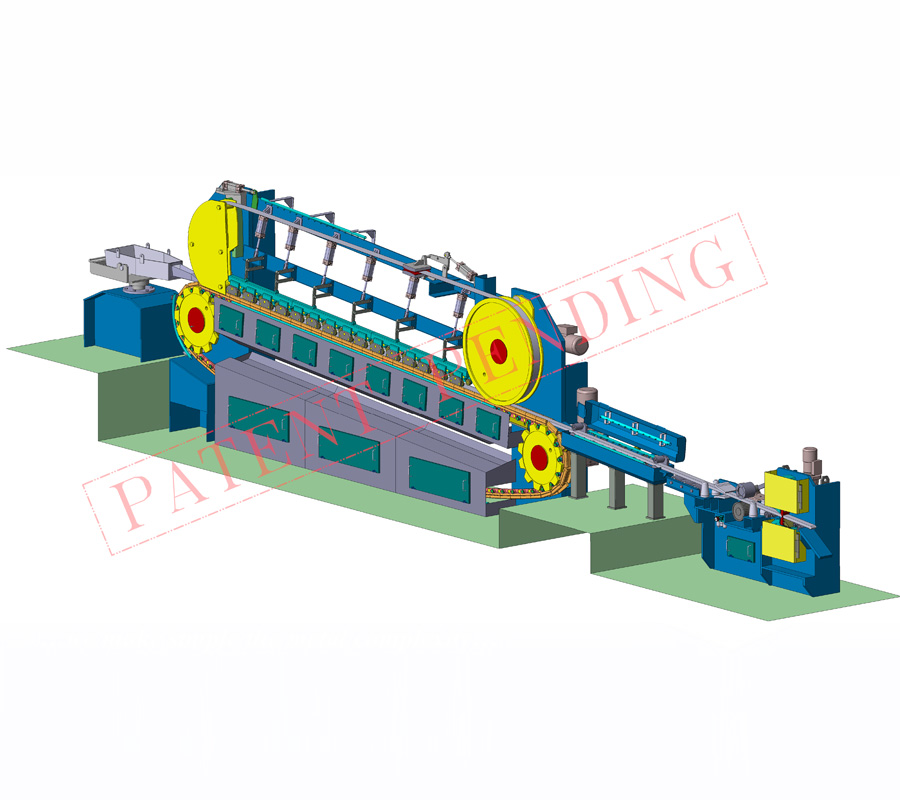

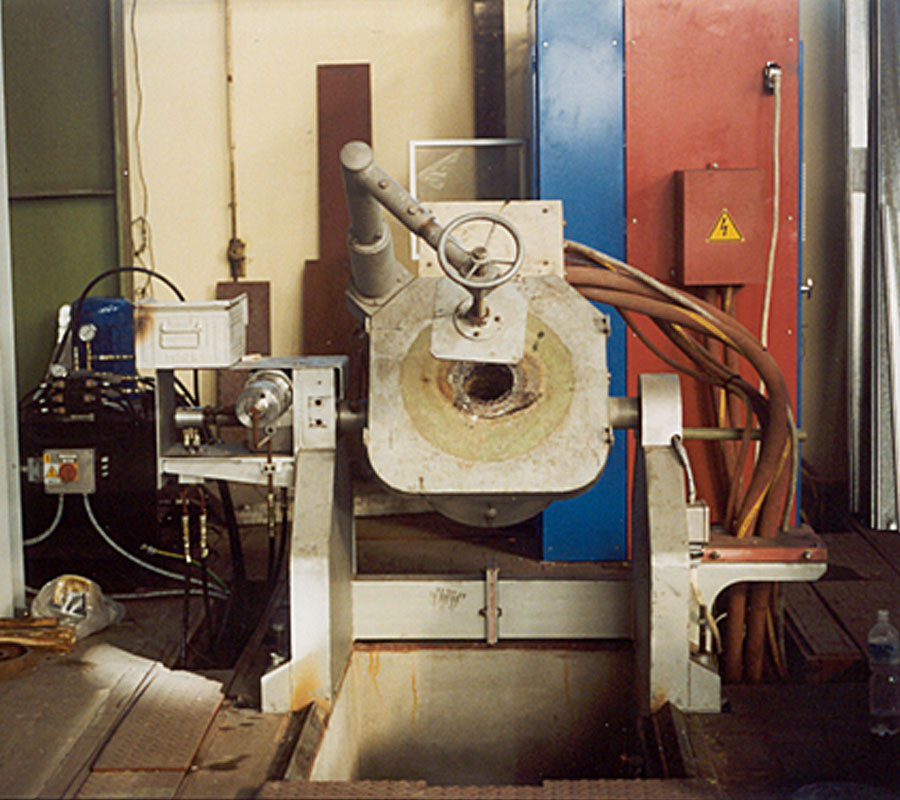

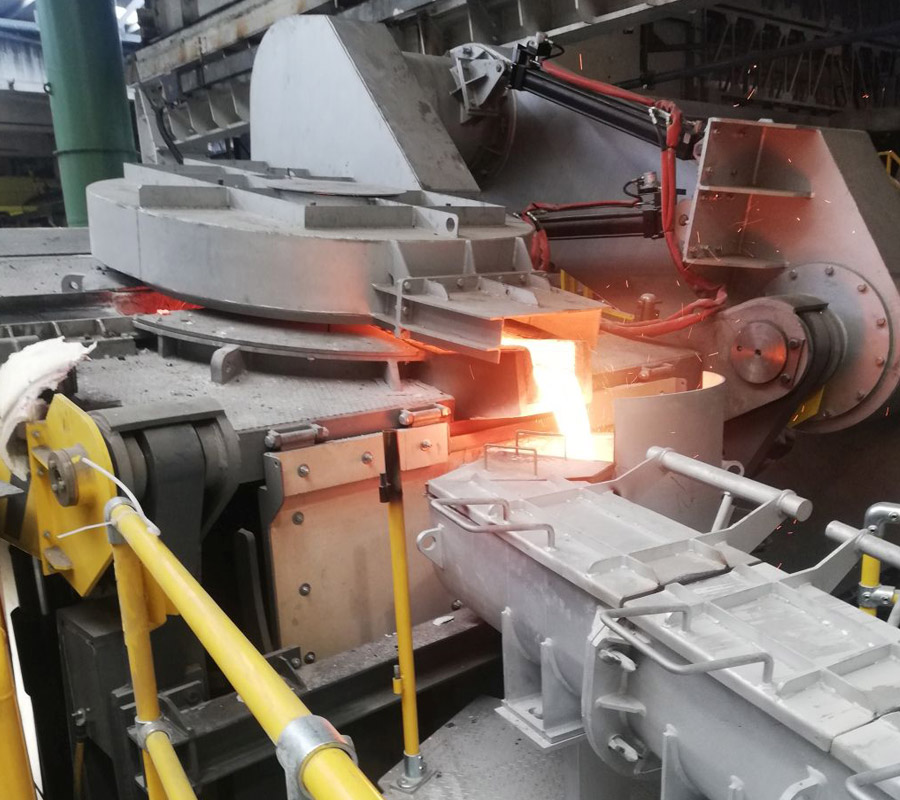

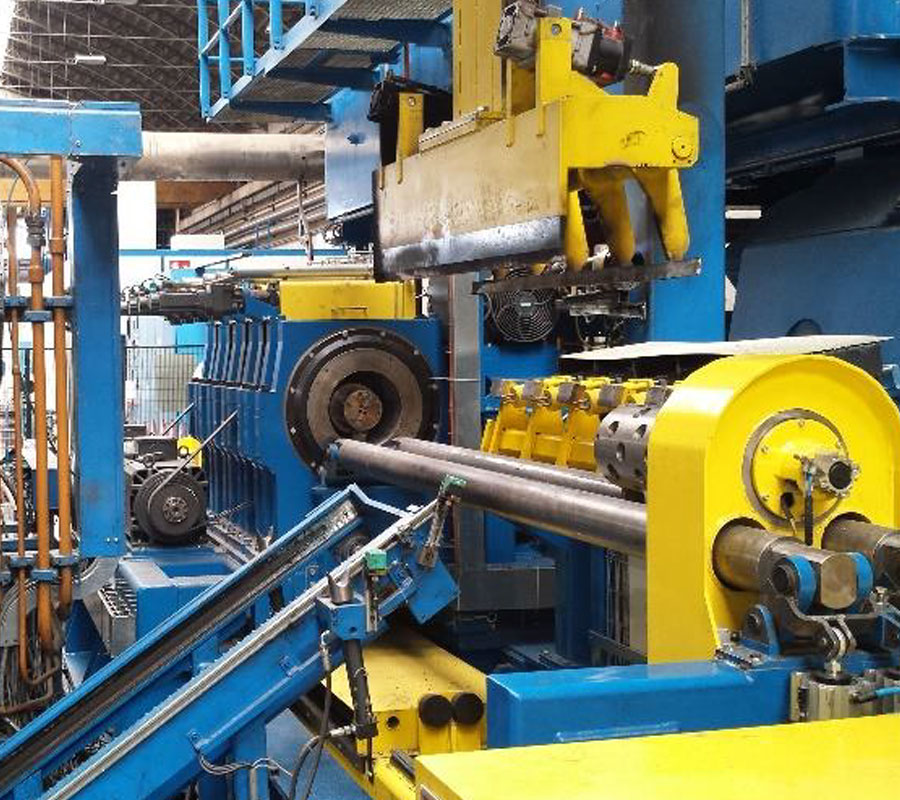

GMS Global Metallurgical Solutions, part of the ENGITEC Group, inherited its technologies package from Calamari S.p.A. - a historical manufacturer of foundry plants in Italy founded immediately after World War II - including design and construction of Induction Furnaces for ferrous and non-ferrous metals melting and Continuous and Semi-Continuous Casting Plants for casting of Copper and Copper Alloys in forms of billets, pipes, strips and wires.

Our Mission

The needs of each individual Customer push us to grow and to innovate our Technology at a global level in the metallurgical sector. Our highly specialized Technicians are constantly trained to develop optimal customized Solutions of Italian Quality.

OUR TECHNOLOGIES

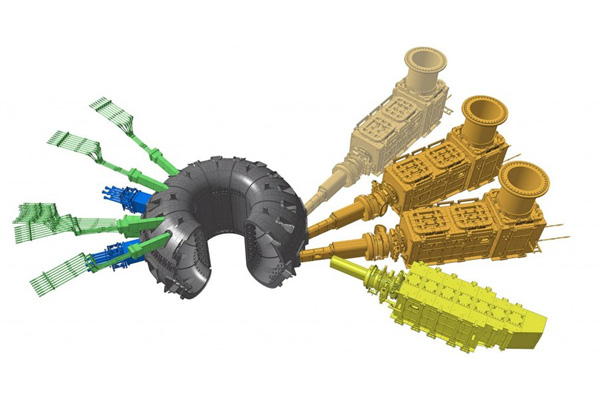

The most important Technologies in the catalog of GMS are

SERVICES

Italiano

Italiano

Latest News